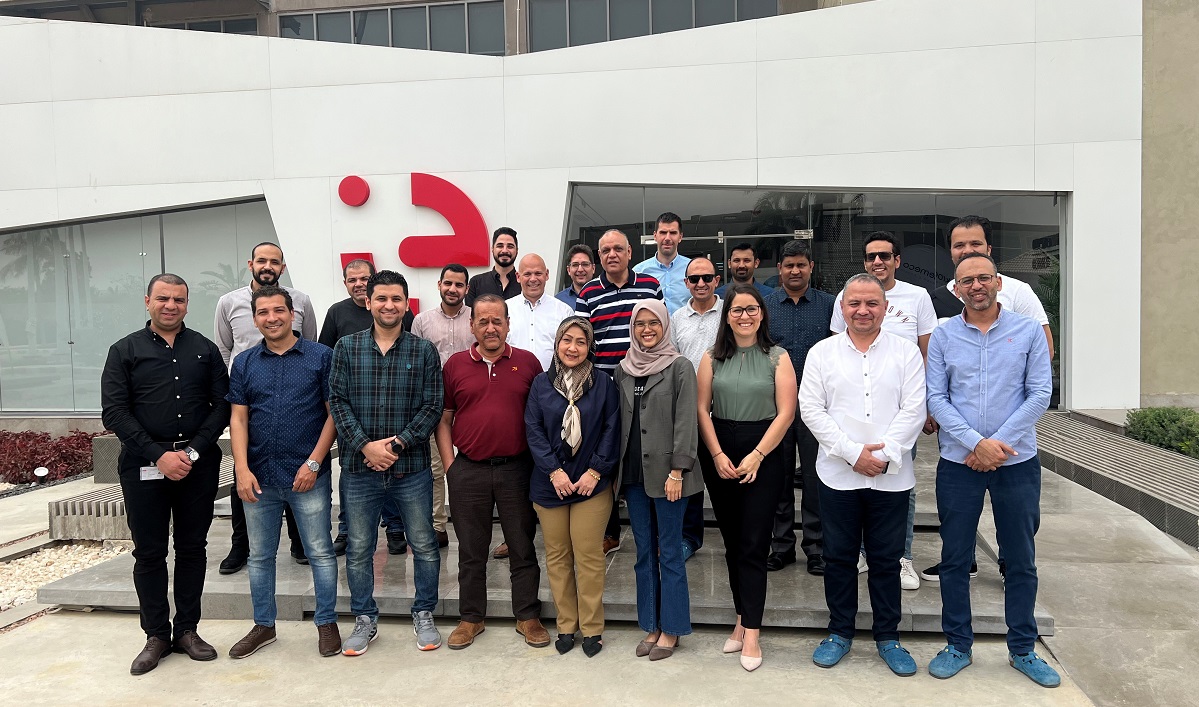

The event brought together Lean experts from Egypt, India, Malaysia, and Slovenia, who gathered to discuss and share their knowledge about Lean principles, methodologies, and practices. Lean, a management philosophy and approach, focuses on maximizing customer value while minimizing waste in production.

Throughout the event, Lean experts provided best practices, shared success stories, and discussed lessons learned from implementing Lean thinking and Lean manufacturing techniques. The participants actively engaged in workshops, exchanging knowledge and insights. We are confident that the shared expertise will greatly contribute to the implementation of new excellent practices in the production facilities.

The Global Lean event proved to be a success, with significant milestones achieved. The strong collaboration among participants will lead to great results and significant improvements in efficiency, quality, and customer satisfaction. One of the key outcomes of the event was the establishment of a shared understanding 5S+1 methodology and measurement of production Key Performance Indicators (KPIs): including Overall Equipment Effectiveness, First Pass Yield, and Direct Labor Efficiency.

Achieving the best Lean principles requires a systematic and committed approach. Iskraemeco’s Lean transformation journey benefits from the support and commitment of our top management. In line with this dedication, we plan to continue organizing regular Global Lean events, with sponsorship from Director of Quality Gregor Kita, Manufacturing Excellence specialist Eva Šturm, and Head of Manufacturing Engineering and Production Miha Kern. By facilitating such collaborative events, we aim to foster a culture of continuous improvement, ultimately providing enhanced value to our customers and stakeholders.