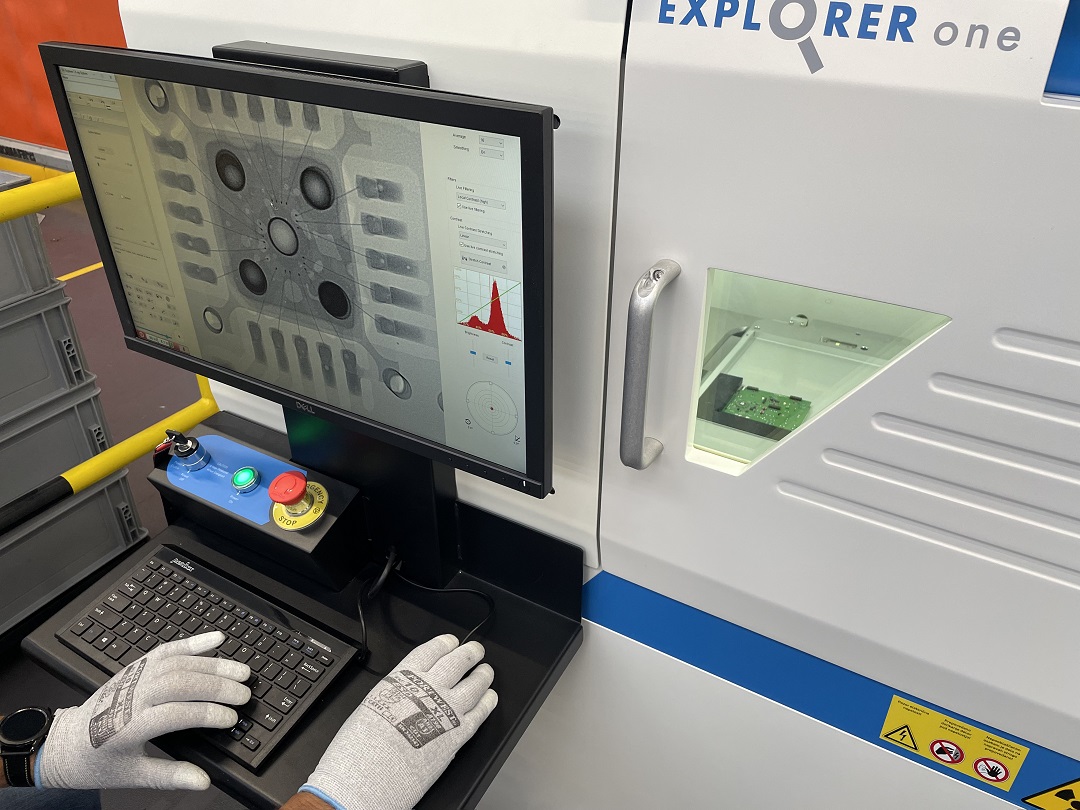

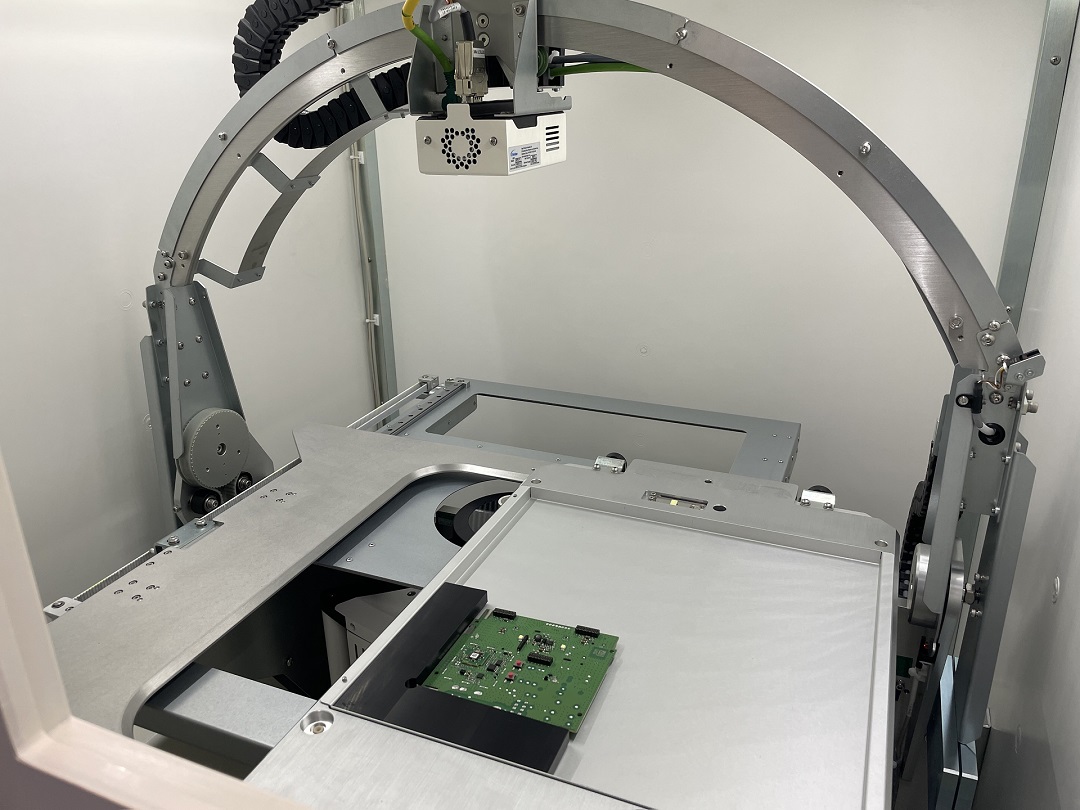

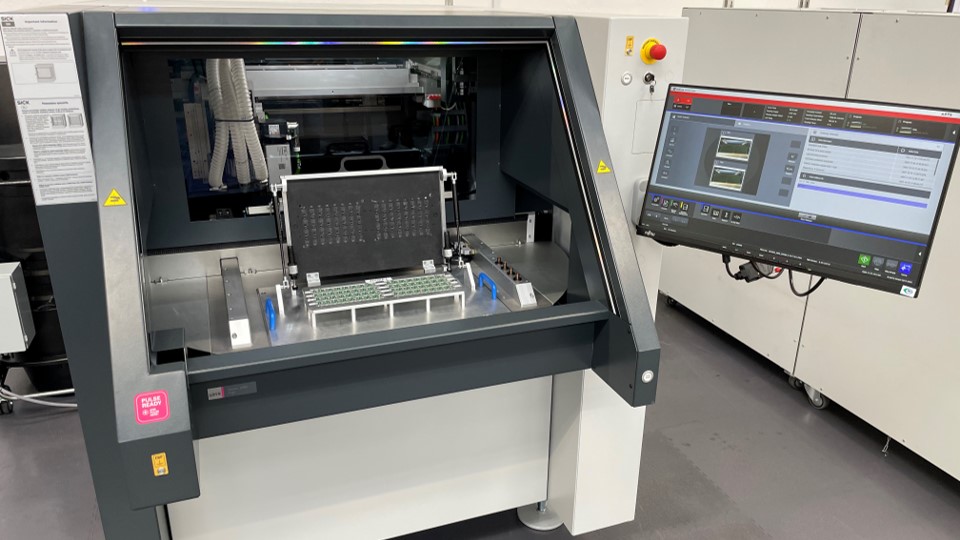

The X-ray device enables the search for hidden defects on electronic circuits. In the production of printed circuit boards, they are most often used to find defects in the joints under the housings of electronic components, which also helps to eliminate bad pieces. In addition, analyzing the causes of defects also improves the production process. Taken together, this helps improve the quality of our products and customer satisfaction.

With the introduction of a newer version of smart meters, the complexity of electronic circuit manufacturing has increased, the number of components that cannot be visually inspected, which also increases the possibility of manufacturing defects. In this case, since the defects are difficult to correct and are discovered only in the final stages of meter production, very high repair or disposal costs may be incurred. Necessary repairs or disposals are reduced by using an X-ray device.

With the X-ray machine, Iskraemeco has acquired an excellent tool for timely detection of defects and improvement of the process of printed circuit assembly. Thus, we offer our customers the service of X-ray inspection of electronic circuits and other defects in products.