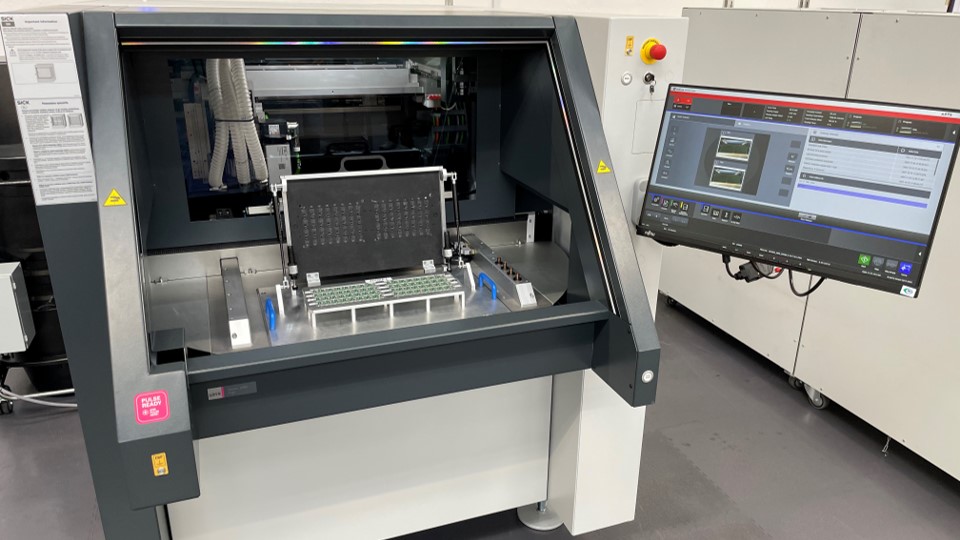

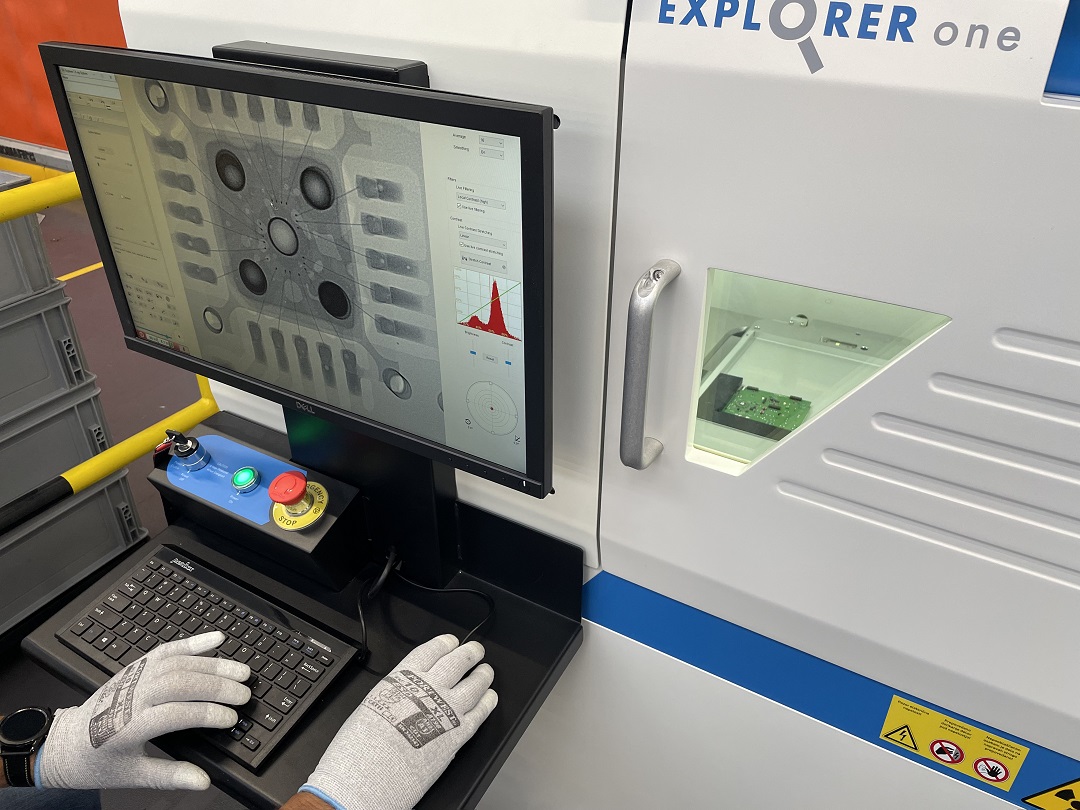

The new machine is used to separate printed circuit boards containing several smaller products connected by “bridges”. Compared to the old process, which used hand saws to separate the circuits, the current process is more reliable and achieves more demanding dimensional tolerances and better quality.

With the help of a precise milling head, the machine is able to separate the circuit boards from each other, achieving better repeatability of the cut, higher dimensional accuracy and shorter circuit separation time. The machine therefore contributes to the optimization of the production process of the most demanding printed circuit boards. By performing this process internally, we can also reduce production costs, which is beneficial not only for us, but also for our customers.